Patio 12x6 Outbuilding Making Plans : Points To Ponder While Constructing A Garden Shed

We used a transit level to craft sure we had soil level. It was around 6 hours labor 4 with my helper and 2 on my own and all 12 posts were up and almost half of the horizontal stringers ran. It's important to accurately place the footings, or piers-it makes the build quicker and easier by preventing constant remeasuring and adjustment. You can see that you'll have to notch top plate and corner studs to fit around porch beams, but once you finish that part, rest of wall and header follow traditional methods. This can cause the shed to go out of true if you don't have (https://shedblueprintsdiy.com/shed-blueprints-8x12-free-shed-plans-for-a-8-x-12-shed) bracing there to keep it square.

The exterior panels will be left the full eight feet wide however, so they cover up end wall frames once all walls are put up. Then, bind them into a solid roof frame. Depending on desired pitch, right materials need to be chosen to achieve the targeted slant. Leave no gaps between the components and sure the overhangs are enough to drain water properly. Install sill plates with a bearing area of at least 48 square inches when sill plate bears on concrete or masonry. This step by step woodworking project is about saltbox shed diagrams. For windows, we used wooden barn sash, which tilt in for ventilation.

If you're planning to build your shed on an elevated base or foundation, it can still be well secured against wind forces. They are a good way to secure a temporary or permanent shed to a foundation. Assemble them on (view website) a flat site to avoid twisting. The amount of storage space you need is important to figure out so you do not end up building too small of a shed. The shed will need to be fastened against uplift. You may cantilever solid lumber floor joists, supporting an exterior balcony according to following table. This means that the wall studs on the floor above will be directly over the wall studs on floor below, even though horizontal wall plates, floor braces and subfloor materials separate the walls.

Processing video...

This is the second decision to craft after choosing your location for the shed. A strong, well-constructed joist system will provide a solid floor foundation for decades. In general practice, 2x8s, 2x10s or 2x12s are used when framing a raised floor instead. When joist hangers are needed, they often look different from standard face-mount hangers. To encourage compliance, local codes are amended to reflect the trend and needs. A ramp for front entrance makes it easier to access the shed with mowers, wheelbarrows or other large items. Set the mudsills on top of blocks running across front and rear of the shed.

You will find everything there is to know about building one right here. Tamp down or dig ground so that you have a nice level surface to support the frame of your floor. That would save you hassle of upside-down nailing in a confined spot. Unfortunately, because of narrow door we had to chop to avoid difficulties listed above we had to remove door's innards so that it would close flat against the wall. This season's solution put too much effort on balancing the boat. Floor joists, constructed from large-dimension lumber, bear weight of the structure above, so notching them isn't recommended.

Cut sheets to right size with a circular saw. The last three rafter pairs are different from the others. Then place timber panels on saw-horses or a cutting table, and cut. They can be used for manufactured shed, or to support other small sheds of the same size. Then windows flashing, then siding yes siding before the roof because the rafters would cap siding and help hold it together. If you are comfortable with using basic hand and power tools, creating your own backyard outbuilding is not hard. Seal doors, windows and other joints with rubber flashing, sill pans and special tapes.

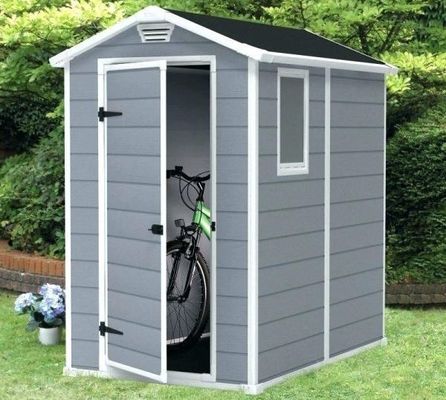

Place marked plates on a flat surface and connect them on each end with full studs, typically called 8-foot studs although they actually will be shorter to allow for the plates. Rip door and window trim and shed corner boards from rough-sawn cedar. Screw plywood strips into place with 2-inch timber screws and a power screwdriver using same spacing technique. The county's regulations were for any structure over 200 square feet would need a permit before building. Make sure joists are rigid before continuing project. The only additional consideration would be adding a latch and lock to keep side panel from being open by thieves.